Maximize Your Construction Projects with Professional Compactors Rental Services

In the world of construction, landscaping, and ground preparation, the importance of proper soil compaction cannot be overstated. Achieving a stable, level, and durable foundation is essential for the success and longevity of any project, from small paving jobs to large-scale infrastructure developments. One of the most efficient ways to ensure optimal soil stability is by utilizing high-quality compactors, which can be rented from reliable equipment providers. Whether you’re a professional contractor or a DIY enthusiast, understanding the different types of compactors available, their benefits, and best practices for use can greatly enhance your project’s outcome. For those interested in exploring flexible and cost-effective solutions, Compactors rental offers a comprehensive range of equipment tailored to various needs.

Understanding the Types of Compactors Available for Rental

Choosing the right type of compactor is paramount to the success of your project. Different surfaces, project scales, and material specifics demand specific equipment, and being equipped with the right tool ensures efficiency, safety, and quality results. Let’s delve into the primary types of compactors available for rental, their applications, and advantages.

Vibrating Plate Compactors: Ideal for Soil and Asphalt

Vibrating plate compactors, also known as wacker plates, are among the most versatile and widely used compacting machines. Their design typically features a flat, heavy steel plate attached to a vibrating mechanism that transmits force directly to the ground. They excel at compacting granular soils such as gravel, sand, and crushed stones, making them ideal for preparing foundations for driveways, patios, or pathways.

Additionally, vibrating plate compactors are highly effective for asphalt work, including patching and laying new asphalt surfaces. Their portability allows for easy maneuvering in confined spaces, making them a preferred choice in urban and residential projects. Modern models often come with features like adjustable vibration settings and ergonomic handles to enhance operator comfort and control.

Trench Rammers and Walk-Behind Rollers: Versatile Equipment for Different Surfaces

For projects involving trench work, such as laying cables or pipes underground, trench rammers or tamping rammers are indispensable. These compact, handheld devices deliver focused force, allowing operators to achieve dense, compacted trenches with precision. They are especially useful in tight spaces or narrow trenches where larger equipment cannot operate effectively.

Walk-behind rollers, on the other hand, are suited for larger areas requiring continuous compaction. These machines can be forward and reverse operated, with varying drum sizes to suit different surface types and project scales. They are particularly effective in compacting soils, asphalt, and other granular materials over expansive zones, ensuring a smooth and stable base.

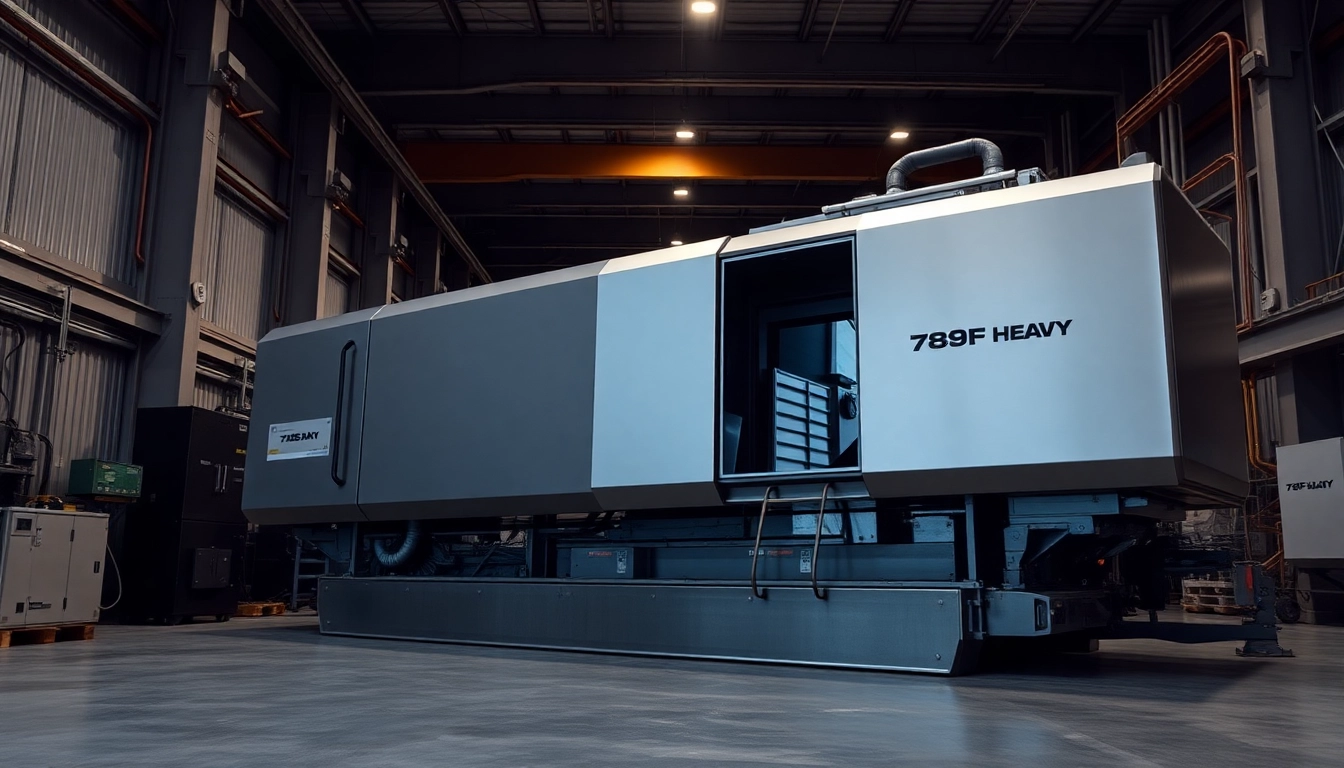

Portable and Heavy-Duty Options: Choosing the Right Compactor for Your Job

Rental providers offer a spectrum of compactors ranging from lightweight, portable units suitable for small-scale projects to heavy-duty machines designed for extensive construction sites. Portable compactors, such as small plate compactors, are easy to transport and handle, making them ideal for DIY projects, garden landscaping, or small paving tasks.

Heavy-duty models, including large trench rollers and vibration compactors, are built to withstand rigorous use and larger surface areas. These are best suited for commercial developments, roadworks, and large infrastructure projects. Selecting the appropriate equipment depends on project scope, surface type, and required depth of compaction.

Benefits of Renting Compactors for Your Construction Needs

Opting to rent compactors rather than purchasing equipment offers numerous advantages, especially for short-term or one-off projects. Here are some compelling reasons to consider rental solutions:

Cost-Effective Solutions for Short-Term Projects

Investing in high-quality compaction machinery can be prohibitively expensive, particularly if the equipment will only be used intermittently. Rental options allow you to access top-tier equipment at a fraction of the purchase price, avoiding depreciation, storage costs, and maintenance expenses. For instance, renting a plate compactor for a few days or weeks is more economical than outright purchase, especially when considering the total cost of ownership.

Additionally, rental companies often include maintenance and repair services, further reducing unforeseen expenses and ensuring the equipment remains in optimal condition throughout your project.

Access to Top Brands and Latest Models Without Capital Investment

Construction technology evolves rapidly, with manufacturers regularly introducing advanced features that enhance performance, safety, and operator comfort. Rental providers typically update their fleets with the newest models, ensuring users benefit from innovations such as improved vibration controls, lower noise emissions, and enhanced fuel efficiency.

This access enables smaller businesses or individual contractors to utilize state-of-the-art equipment, leveling the playing field with large firms that typically own extensive machinery inventories.

Improved Safety and Efficiency with Well-Maintained Equipment

Rental companies prioritize safety and operational efficiency by maintaining their equipment, performing regular inspections, and adhering to safety standards. The use of reliable, well-maintained compactors reduces downtime, minimizes operator fatigue, and enhances work quality. Furthermore, rental staff often provide training or guidance on proper operation, which helps prevent accidents and ensures optimal results.

Step-by-Step Guide to Renting the Perfect Compactor

Securing the right compactor involves a systematic approach, from assessing your project needs to understanding rental terms. Here’s a comprehensive guide to streamline this process:

Assessing Project Requirements and Choosing the Right Equipment

Begin by evaluating the scope of your project, including area size, surface type, and depth of compaction required. Take note of specific conditions such as confined spaces, access limitations, or surface material peculiarities. For example, asphalt paving might necessitate a different machine than soil compaction.

It’s beneficial to consult with rental providers or industry experts who can recommend appropriate equipment based on your detailed project parameters. Proper assessment ensures you select machinery that provides the best balance between performance and cost-efficiency.

Finding Reliable Rental Providers Near You

Location and reputation are vital. Search for reputable suppliers with positive customer feedback, a diverse fleet of modern equipment, and transparent rental policies. Popular options include local tool hire centers, national rental chains, and specialized construction equipment providers. Use online directories or local listings to find the nearest supplier, and consider visiting their premises to inspect equipment quality.

Many providers now offer online booking and delivery services, streamlining the rental process and saving time.

Understanding Rental Terms, Costs, and Return Policies

Carefully review rental agreements to understand costs, including base rental rates, delivery, pickup charges, and deposits. Clarify the rental duration, late return policies, and procedures for equipment damage or malfunction. It’s also important to understand maintenance responsibilities and safety requirements.

Transparent communication minimizes unforeseen expenses and ensures you stay within budget. Always request detailed receipts and keep records of all transactions for future reference.

Best Practices for Operating and Maintaining Rental Compactors

Proper operation and routine maintenance not only prolong the lifespan of the equipment but also safeguard personnel and ensure effective compaction. Follow these essential practices:

Pre-Use Inspection and Safety Checks

Before starting, conduct a thorough inspection: check for visible damage, fluid levels, electrical connections, and safety features such as emergency stops and shields. Confirm that vibrating surfaces are free of debris and that handles are secure.

Always review safety procedures, wear appropriate personal protective equipment (PPE), and ensure all operators are trained and familiar with the machinery. Adherence to safety standards reduces accident risks and operators’ liability.

Proper Handling and Technique for Effective Compacting

Use the equipment as intended—avoid overloading or forcing the machine into obstacles. Maintain steady, overlapping passes to ensure uniform compaction. Adjust vibration frequency based on surface conditions to optimize performance.

For example, softer soils may require higher vibration levels, while dense materials benefit from slower, more deliberate passes. Operator ergonomics—such as correct stance and grip—also affect effectiveness and fatigue.

Routine Maintenance and Troubleshooting for Longevity

Perform daily checks on lubrication, fuel levels, and electrical components. Clean the equipment after each use to prevent mud or debris buildup. Address minor issues promptly—such as replacing worn parts or tightening loose bolts—to prevent costly repairs.

If operational problems arise, consult the manufacturer’s manual or contact the rental provider. Regular maintenance maximizes uptime, preserves the equipment’s value, and ensures safety compliance.

Measuring Success: How to Optimize Your Compactor Rental Investment

Optimizing the return on your equipment rent involves continuous monitoring and strategic planning. Implement these best practices:

Monitoring Project Progress and Quality of Compaction

Use established metrics such as compaction density tests and surface smoothness measurements to evaluate effectiveness. Document each pass, and periodically inspect the material’s compaction depth and uniformity. Employing technologies like electronic density testers enhances accuracy and provides data-driven insights.

Timing and Scheduling for Maximum Efficiency

Coordinate equipment availability with project timelines to prevent delays. Plan compacting activities during favorable weather conditions, typically avoiding rain or extreme heat, which can compromise soil stability and worker safety. Sequencing tasks efficiently reduces idle time and accelerates project completion.

Feedback and Service Improvements for Future Rentals

Post-project evaluation is crucial. Gather feedback on equipment performance, rental experience, and operator safety. Use insights gained to refine your procurement strategy, choose better suppliers, and negotiate more favorable terms. Developing ongoing relationships with trusted rental providers can lead to discounts and priority access to new models.